Accurate thickness measurement for both alloy deposits can be obtained using proper thickness standards.

Zinc nickel plating thickness.

Zinc plating with black chromate offers better corrosion resistance and anti galling characteristics than black oxide.

It can be formulated to meet a variety of corrosion resistance specifications.

For comparison zinc plated and passivated parts of a similar thickness are expected to achieve only 120 hours considerably less.

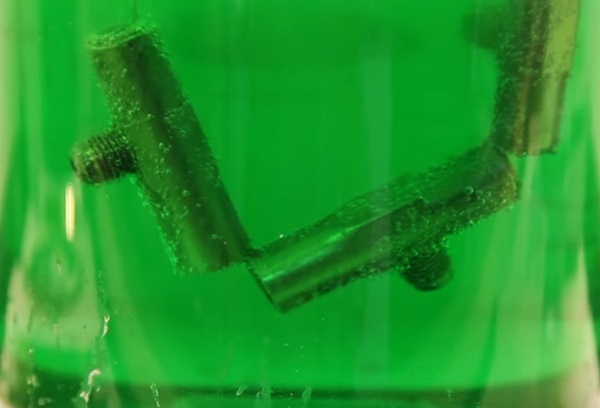

The process is rack plating.

What are the xrf testing requirements for plating zinc nickel alloy.

The zinc plating process can be considered an excellent primer for paint surfaces with the paint protecting the zinc giving a lasting protection.

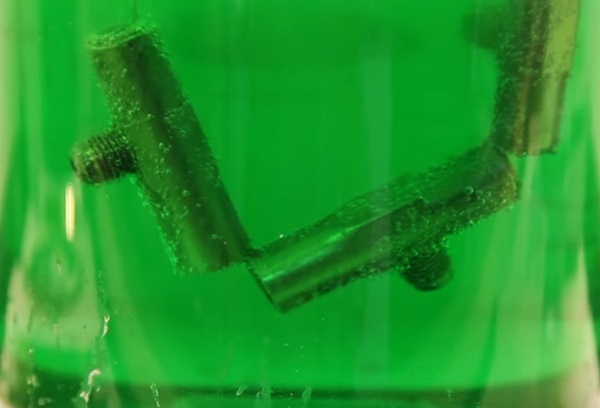

X ray fluorescence xrf is a common technique used for quality control of zinc and zinc nickel alloy plating deposits.

For zinc nickel plating what should be the correct criteria to determine the correct plating thickness.

Interpreting thickness and salt spray specifications for zinc nickel plating march 21 2013.

For some applications designers may opt to use zinc nickel plating instead of zinc plating for further corrosion resistance the above table will not be applicable.

Is 8 microns minimum.

To shed more light on our zinc plating thickness issue most of our in house thread ring gages are class 2a gages.

Zinc nickel is a high performance coating that provides exceptional corrosion protection in harsh environments.

In the past we have attempted to produce threads to a undersize pitch diameter less 4 times plating thickness and use the 2a gages to check afterplate condition.

Standards for zinc nickel plating typically require unpassivated parts coated with 10µm of zinc nickel to withstand 500 hours or more of neutral salt spray testing before red corrosion.

Please tell us what thickness you require on your purchase order.