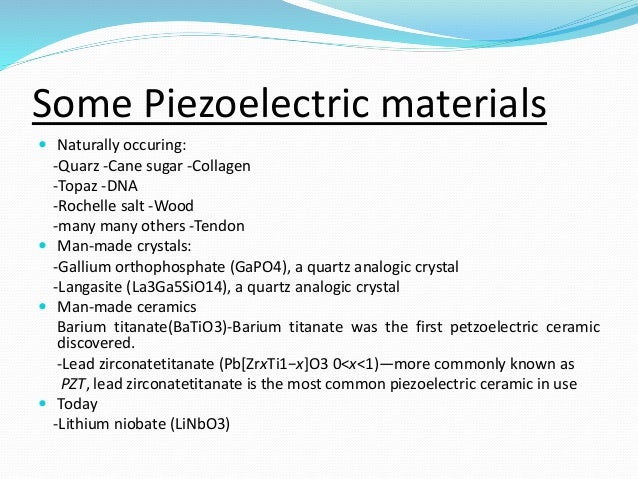

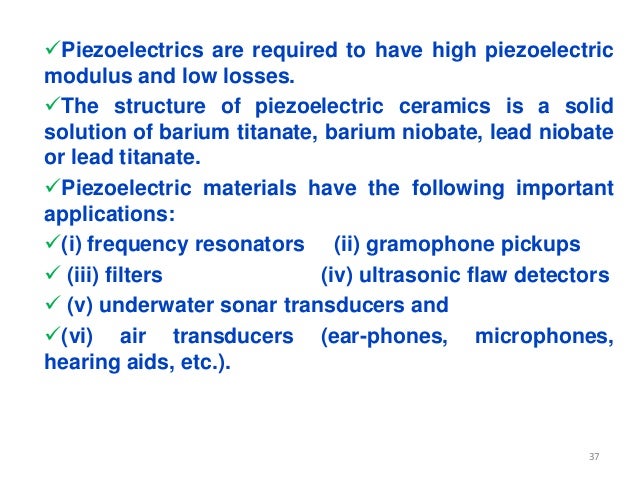

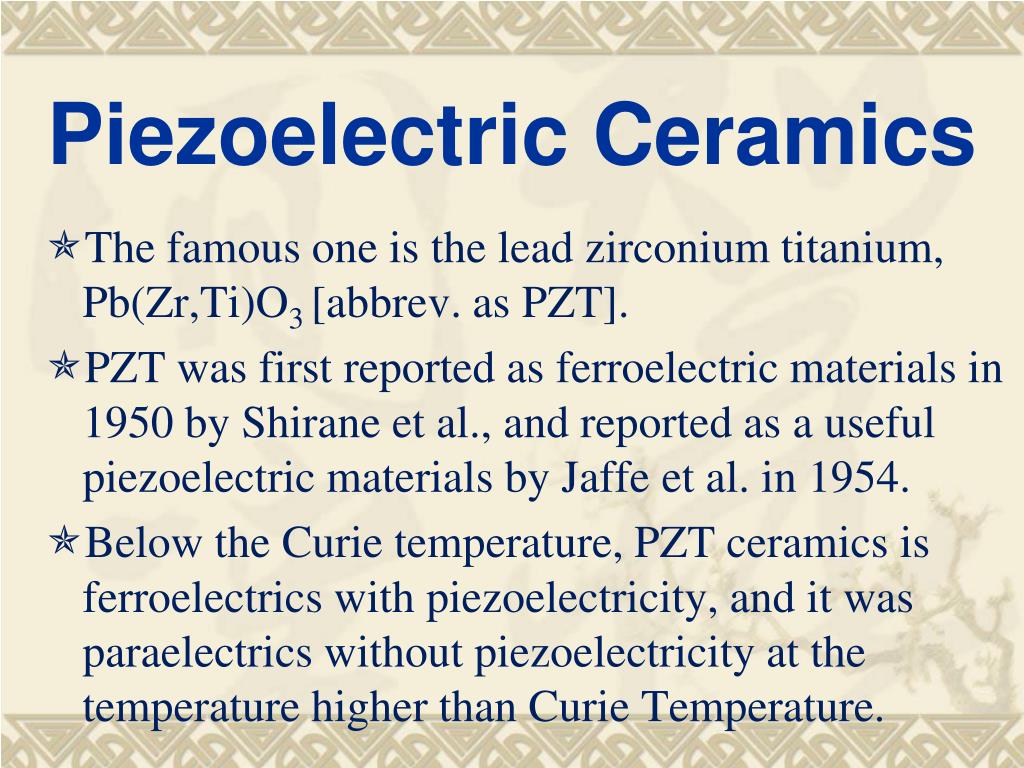

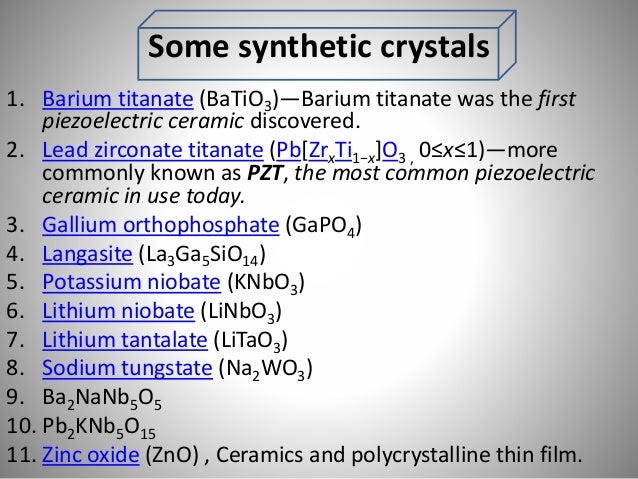

Pzt lead zirconate titanate is the most common piezoelectric ceramic in use today lithium niobate linbo3 ffm 30 07 2010 16 applications sensor.

Ceramic piezoelectric materials ppt.

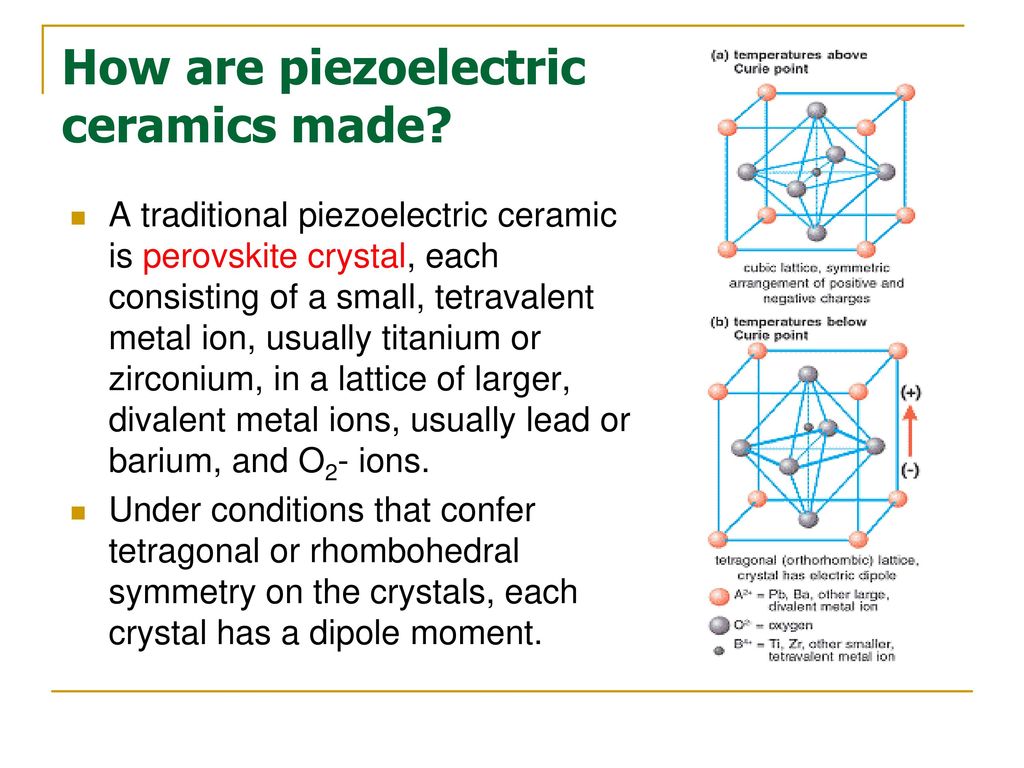

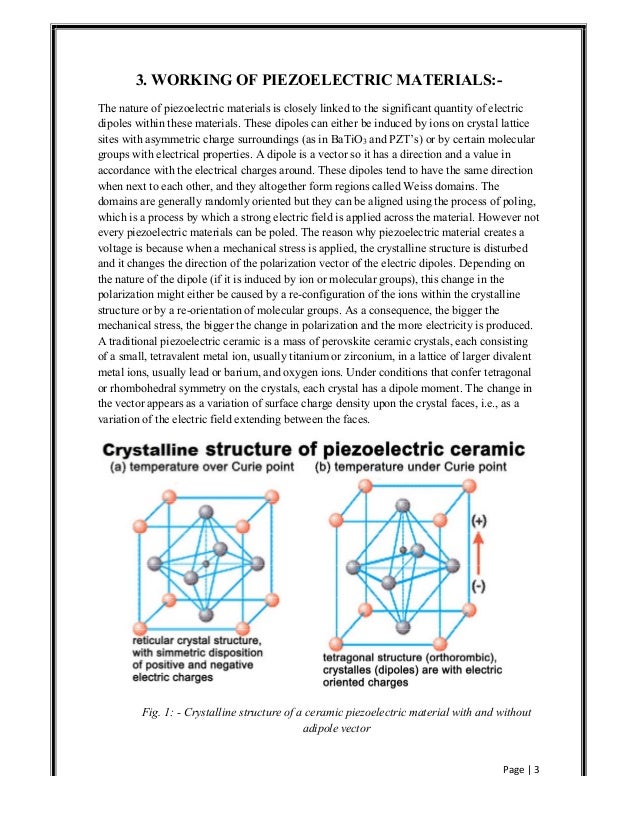

Ceramics exhibiting piezo electric properties belong to the group of ferroelectric materials.

A random orientation of domains prior to poling.

4 piezoelectric ceramic materials t tanaka denpa shinbun 5 piezoelectric ceramics and their applications electronic materials association denpa shinbun 6 new ultrasonic wave technologies e.

Wada nikkan kogyo shinbun 8 ultrasonic circuit s.

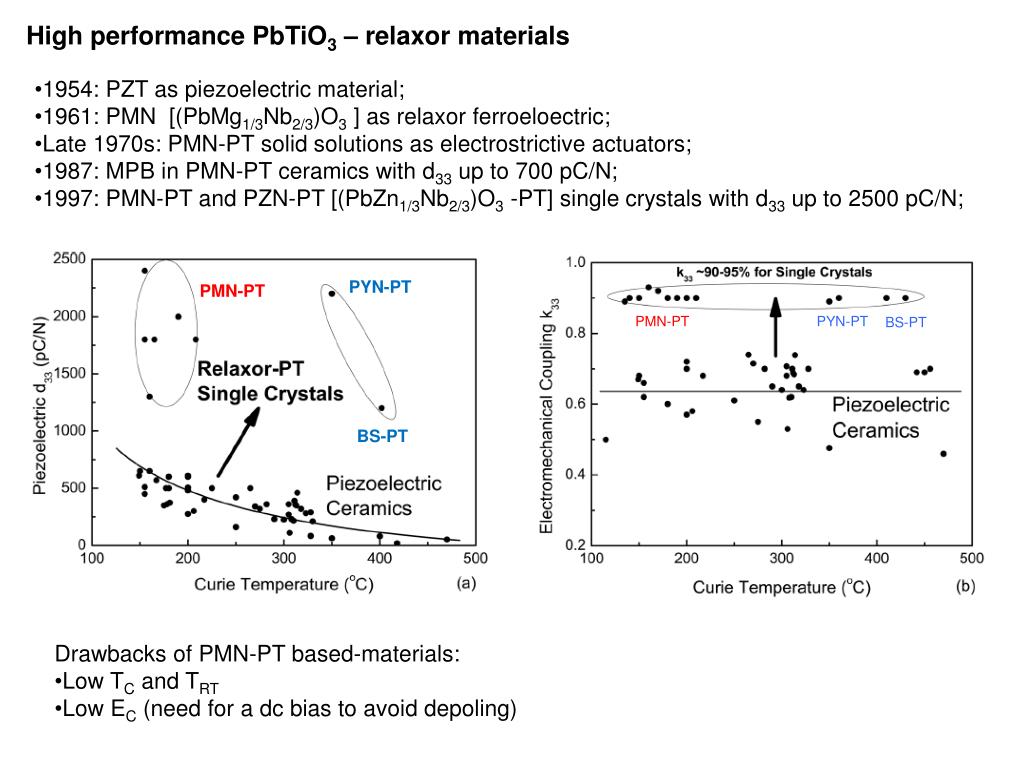

Today s systems are almost exclusively based on lead zirconate titanate pzt.

Porcelain is a ceramic material made by heating materials generally including clay in the form of kaolin in a kiln to temperatures between 1 200 c 2 192 f and 1 400 c 2 552 f.

I e they consist of mixed crystals of lead zirconate pbzro 3 and lead titanate pbtio 3 piezo ceramic components have a polycrystalline structure comprising numerous crystallites domains.

The ability of silicate ceramic materials to provide thermal insulation is also utilized in heating environmental and thermal engineering applications.

Piezoelectric ceramic materials are not piezoelectric until the random ferroelectric domains are aligned by a process known as poling.

Piezoelectric materials convert electrical ener gy into mechanical energy and vice versa.

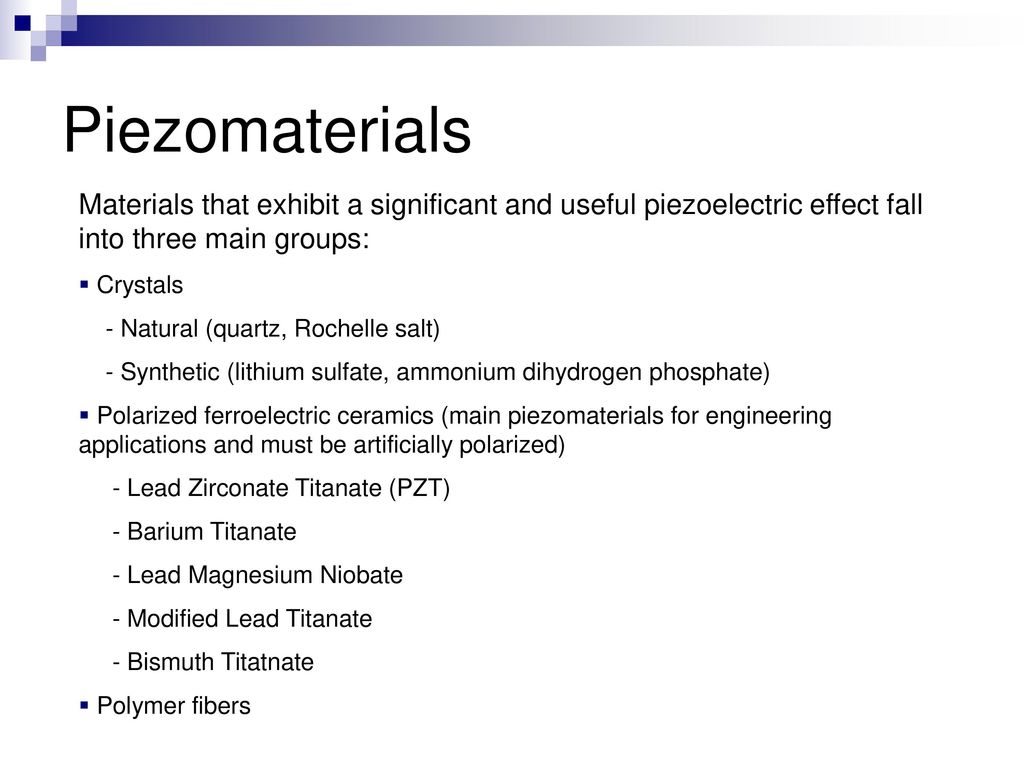

The third category is composite piezoelectric materials made up of organic polymer base materials embedded in sheet rod rod or powdered piezoelectric materials.

Piezoelectricity is the ability of some materials to generate.

1 5 they can be used to sense changes in pressure and strain in the environment and can generate electrical responses.

Mori nikkan kogyo shinbun 7 ultrasonic engineering h.

These electrical signals can be input to feedback systems to stimulate movements in actuators to trigger alarms or to switch the systems on or off.

The piezoelectric effect is now used in many everyday products such as lighters loud speakers and signal transducers.

Pi ceramic provides a wide selection of piezoelectric ceramic materials based on modified lead zirconate titanate pzt and barium titanate.

The designations of soft and hard piezo ceramics refer to the mobility of the dipoles or domains and hence also to the polarization and depolarization behavior.

Poling consists of inducing a dc voltage across the material.

The disadvantage is that the piezoelectric strain constant d is low making it very limited as an active emission transducer.